Source: Print Quality Guide

Category Archives: 3dprinting

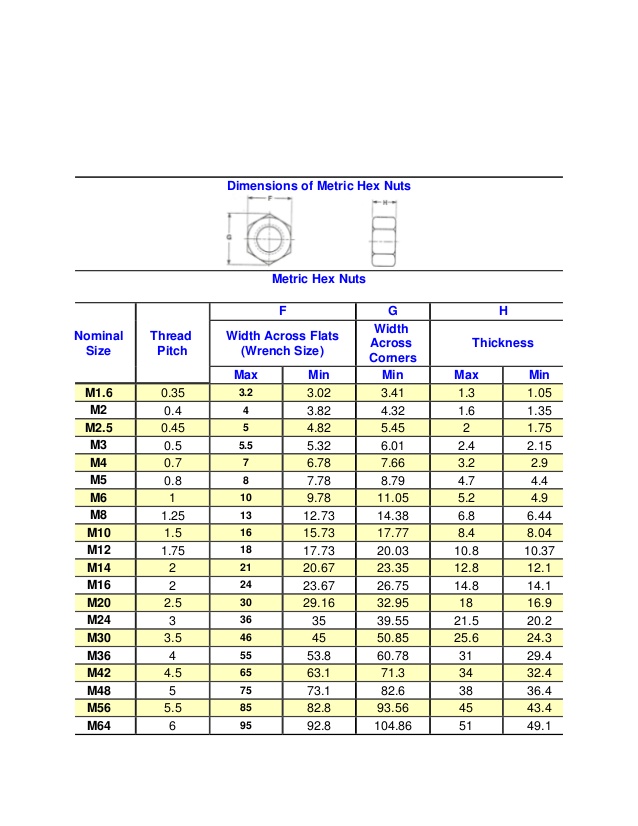

Dimension of Metric Hex Nuts

Metric Flat Square Nut Dimensions

How to Make a USB Laptop Keyboard Controller

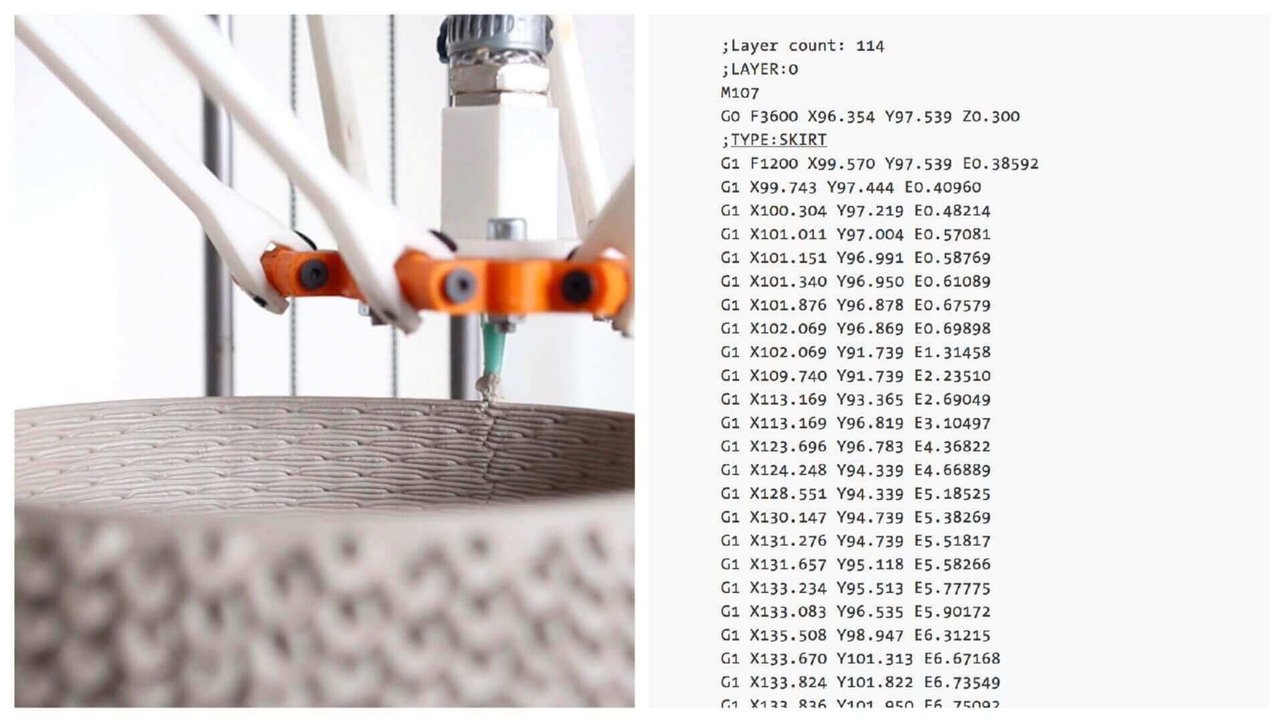

3D Printer G-code Commands List & Tutorial | All3DP

Universal bitting depth key decoding utility | kstoerz.com

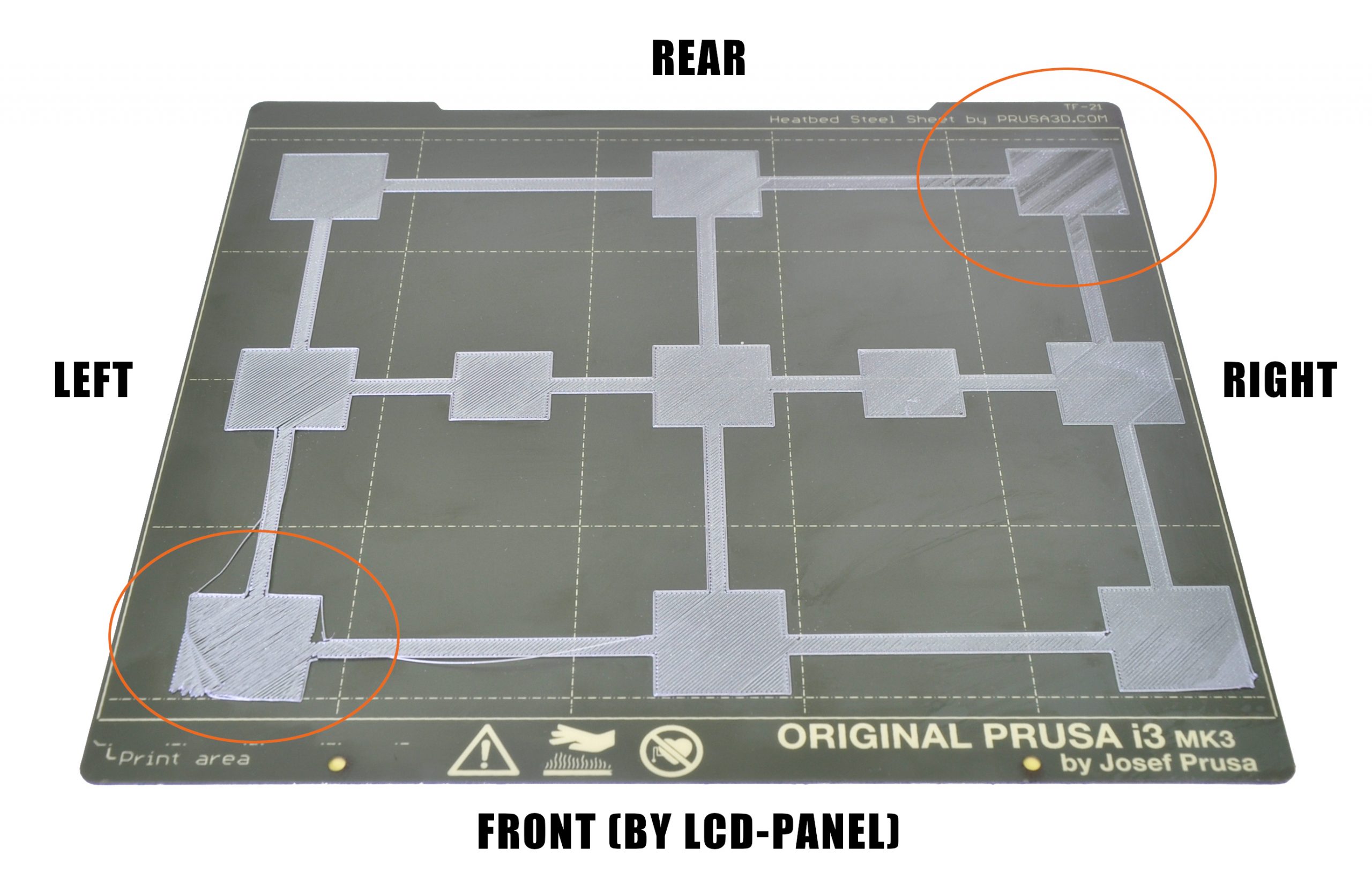

Prusa Knowledge Base | Bed Level Correction

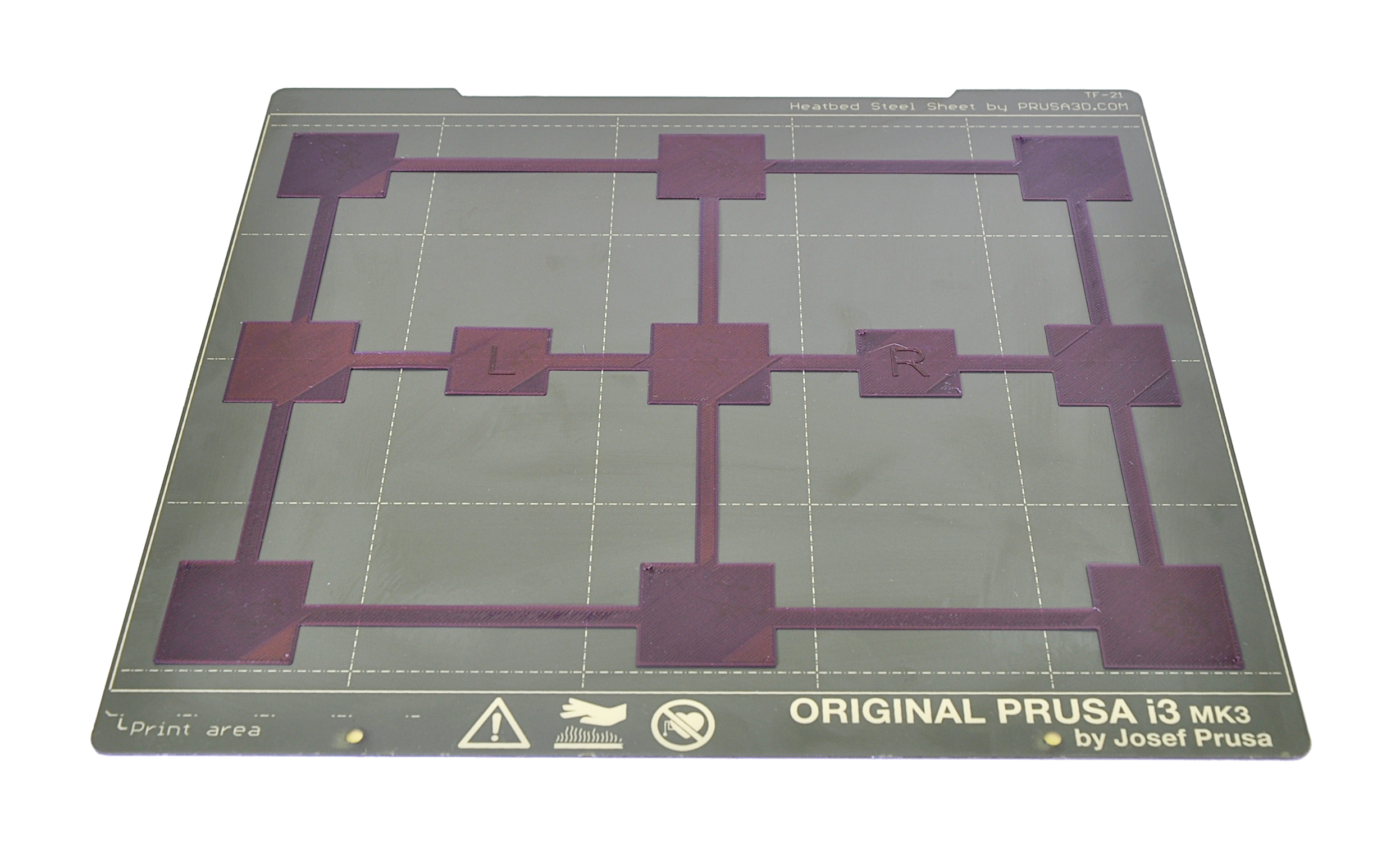

Together with the Mesh Bed Leveling, the Bed Level Correction is an important feature designed to allow users to compensate for even the slightest imperfections in the first layer. It allows to virtually raise or lower the heatbed on the Left, Right, Front and Back sides, essentially enabling you to have a different Live Adjust Z value on each of the four sides of the heatbed. This feature is most beneficial if you frequently need to use the entire area of the heatbed.

How to use Bed Level Correction

Starting from firmware 3.5.2, the adjustment limit is +/- 100 microns (μm) instead of +/- 50 microns (μm) in the previous versions. Even 20 microns can make a huge difference, so when using this function, make small incremental changes. Just like in the Live-Z adjust, negative values lower the nozzle closer to the heatbed.

- Run a First Layer Calibration to get a good baseline calibration.

- Download and slice this test model for your printer version using the Prusa Slicer’s default PLA settings, 0.20 mm layer height.

- Print the g-code prepared in the previous step with a PLA filament (ideally light and opaque color). The print is just one layer high and takes up most of the printable surface. You do not have to print the entire file, stop the print as soon as the differences in layer height across the plate are obvious.

- Evaluate where the layer is too squished and full of scars and where there are gaps in between the lines. In the photo below, the lines are way too squished in the top-right corner, and the nozzle is too far away in the bottom-left.

In the example above you want to adjust a minus-value on the left, bringing the nozzle closer and a plus-value on the right, moving the nozzle away. You may also need to adjust the distance front and back, but do a test print after adjusting the left and right side.

- Go to the LCD Menu -> Calibration -> Bed level correction. There, you can adjust Left/Right/Front/Rear values (understood from your point of view, as you are looking at the printers LCD).

- Edit the values, we suggest going in steps of +/- 10. These values will be added to the baseline Live Z value set in step 1. Remember, a negative value will decrease the distance between the nozzle making the layer more squished. A positive value will increase the nozzle-bed distance, curing the scars on your first layer.

- Repeat steps 3 to 6 until you are satisfied with the result (photo below for inspiration).

For example, let’s say your Live adjust Z value is -1.000 and that the layer is too squished in the rear and that you see gaps between the lines on the right side.

- Rear: you need to enter a positive value (at the end it will be 25 for example) to make the layer less squished

- Right: you need to enter a negative value (at the end it will be -10 for example) to make the layer more squished

– Repetier Software

Corona Virus banner illustration – Microbiology And Virology Concept – by Mike Fouque 1 Object Placement Import one or more 3D models and place, scale, rotate or duplicate them on your virtual bed. 2 Slice Slice your plate with different Continue reading →

Source: – Repetier Software

Setting up Palette 2 with prusaslicer and p2pp

You need python 2.7 or 3.7 installed on your computer.

Octoprint needs the Palette 2 plugin installed https://gitlab.com/mosaic-mfg/palette-2-plugin

Grab the P2PP scripts, unpack it somewhere on your computer. There are instructions for setting up & configuring the p2pp scripts. Decent video at https://www.youtube.com/watch?v=JuTdq-IlRj4&t=1s

Scripts are at https://github.com/tomvandeneede/p2pp

Other useful links: https://support.mosaicmfg.com/Guide/Slic3r-PrusaSlicer+and+Chroma+Setup/76

Configure PrusaSlicer for p2pp

Printer settings tab – Capabilites:

extruders = 4

single extruder multimaterial = yes

enable variable layer height = no

once those are done, you will have options for “Single extruder MM setup” – select that and set all those values to zero / unchecked.

For extruders 1 – 4, change the filament color so you can see what is happening on the Plater tab.

Save the new printer profile as a new name.

Print settings tab –> Multiple extruders –> Wipe tower -> Enable= on, Prime all printing extruders = off

Output options-> Post processing scripts -> insert path to p2pp.bat

Output filename format -> edit format string so that it ends in .mcf.gcode instead of just .gcode

Now go back to printer settings tab

Custom Gcode –> Start G-code. Insert code in bottom of that section: code from https://github.com/tomvandeneede/p2pp

edit the code inserted: P2PP PRINTERPROFILE= THe value for this needs to come from a previously generated chroma processed gcode file. The line will begin with 022. Copy the string (without the initial capital D) and paste that as the value for “P2PP PRINTERPROFILE”

The next couple values can come from the Chroma postprocessor app. Start it, edit the printer profile, and look at the values for Min|Max|Early Transistion Length and Target Position (defaults are probably 140mm, 140mm, 140mm and 40%).

Edit the values for

P2PP SPLICEOFFSET= Make this number 40% of the Min Early Transistion Length (ie; 140mm – 40% = 56mm) Use the actual number found in your Transistion Target field – might not be 40.

P2PP MINSTARTSPLICE=100 this is due to hardware limitations, leave it alone

P2PP MINSPLICE=80 Same as above

The values for P2PP MATERIAL_TYPES 0_0_0 are as follows Heat factor, compression factor, cooling factor. Used for tuning. You can look at material profiles in the Chroma post processor to see what you have set in there

;P2PP LINEARPING (leave this in)

;P2PP LINEARPINGLENGTH=500 – might need to tweak this – too low and printer may pause. too long it it may not be well calibrated. Dont go below 350

;P2PP EXTRAENDFILAMENT=150 – figure the length of your hot end + bowden tube and add a little extra so you can pull filament out

Not sure about the SIDEWIPE settings yet…

Now in the “After layer change G-code section append this code: ;LAYER[layer_num]

Now off to Filament Settings Tab

Go to Advanced–> Rammer settings button. Set Total Ramming Time to zero, No Ramming at all.

Now to configure Purging Volumes.

Go to Plater tab, click Purging volumes button. To get the number for the unloaded and loaded fields, take the number from the Chroma post processor, look in the printer profile -> Transistions tab and see what number the Min Transistion length is. That number is in millimeters. Prusaslicer wants cubic millimeters. 1mm of filament is basically 2.4 cubic mm, so multiply the min transistion length number by 2.4. Then divide that number in half, and insert half in unloaded and loaded fields. If you need to finetune it later, like when switching from a dark color to light color, you could adjust the ratio between loaded / unloaded, but the total of the two boxes should still equal (min transition length * 2.4).