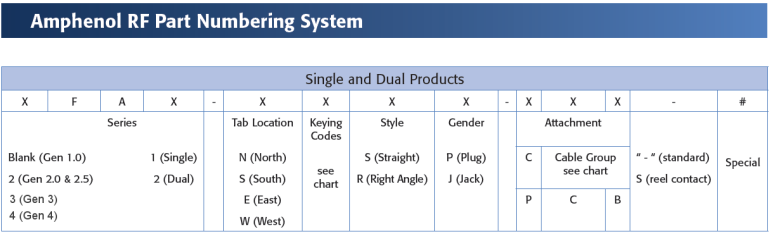

FAKRA Part Numbers Explained:

To search for FAKRA parts for your next project follow this link. When you get there, you may find yourself a bit confused at which part number you should select! The key codes and colors were discussed in Part 1 of this series and here we will break down the part number scheme to help you better choose your parts:

Let’s go through an Example P/N:

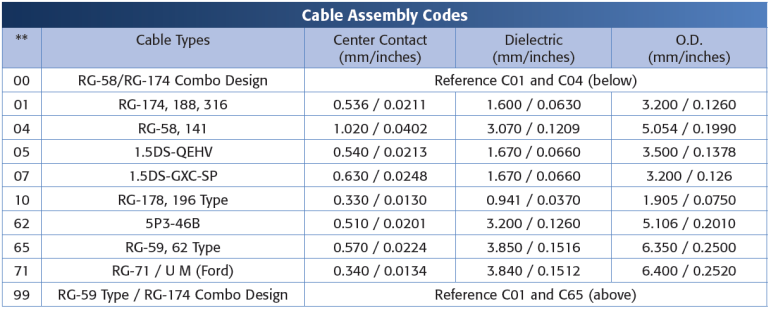

This part is a Gen 2, Single position, North tab location, D key code, Straight Plug, Cable connector for Cable Group 01 (see below), with a standard contact, in-line connector. How can you tell the difference between Gen 2 vs. Gen 2.5? That will be discussed in the Generations section of this post!

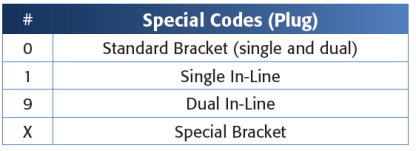

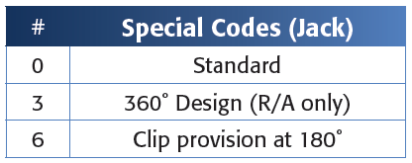

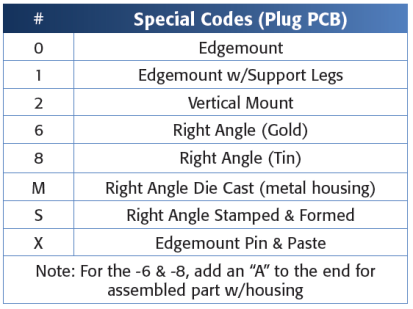

Special Codes:

This a Gen 1, Single position, North tab location, A key code, Straight Plug, PCB, vertical mount connector.

FAKRA Generations Explained:

Generation 1: FAKRA Generation 1.0 utilizes a modified metal SMB connector embedded within a plastic housing unit for ease of identification and assembly. These plastic housings are designed with visually and mechanically coded and keyed tooling to eliminate assembly errors. Our standard FAKRA connectors are designed to perform up to 4 GHz and meet the electrical, mechanical and environmental standards of the automotive industry. Generation 1.0 typically features five separate component parts. Gen 1 FAKRA is a die cast or machined body with machined contact. Can assemble with hand tools.

Generation 2: FAKRA Generation 2.0 offers reduced installation costs for our customers via a pre-assembled housing unit. This pre-assembled housing eliminates two loose components and their associated assembly and handling costs. Due to this component reduction, Generation 2.0 features three separate components to install versus Generation 1.0’s five separate components. Summary: Gen 2 FAKRA is a die cast or machined body with machined contact. Gen 2 is an evolution of Gen 1. Can assemble with hand tools.

Generation 2.5: FAKRA Generation 2.5 offers the same pre-assembled housing units and design improvements as Generation 2.0, but center contacts are provided on a tape and reel for automated distribution and placement. Summary: Gen 2.5 FAKRA is a die cast body and has a stamped contact, a significant modification from Gen 1 and 2. The contacts are sold separately on tape and reel. This Generation requires automated tooling to assemble.

Generation 3: Generation 3 currently only exist for jacks (not applicable for plugs). Gen 3 jacks incorporate the same construction features as the Gen 2.5 jacks. Additionally, the Gen 3 has been enhanced with a closed-entry interface and a protected outer contact, making the connector more robust than traditional SMB’s. The stamped and formed center contact continues to be supplied on a reel, allowing for semi-automated termination onto the cable. Summary: Gen 3 FAKRA is a die cast body and has a stamped contact, an evolution of Gen 2.5. The contacts are sold separately on tape and reel. This Generation requires automated tooling to assemble.

Generation 4: Gen 4 plugs and jacks are designed for fully automated termination by the user. Not only the center contacts but the connector bodies themselves are supplied strip-fed on tape and reel. This connector offering will be directed to the high volume users whose factory utilize high-speed automated cable assembly production. The connectors are stamped and formed construction. The FAKRA connector housings for Gen 4 are removable, permitting field replacement if necessary. Summary: Gen 4 FAKRA is fully stamped and formed – both body and contact! Huge leap forward from Gen 3. All components are sold separately on tape and reel. This Generation requires fully automated tooling to assemble.

Recommendations:

If you are interested in incorporating FAKRA connectors into your non-automotive application, Gen 1 or Gen 2 products are likely your best option. These can be terminated by normal hand tools and are shipped complete. If you are a high volume automotive supplier, a Gen 2.5, 3, or 4 product is going to be the ideal product for your application. These require special tooling and setups that are only typically found in very high volume applications.

As always, feel free to contact us with any questions you have!

Next in the series: Custom FAKRA capabilities, sealed FAKRA, FAKRA applications, and uses outside of automotive! Check out the latest FAKRA cutsheet for our Gen 3 product offering including the contacts on tape and reel.

Source: FAKRA Series Part 2: Connector Part Number and Generations Explained | Amphenol RF