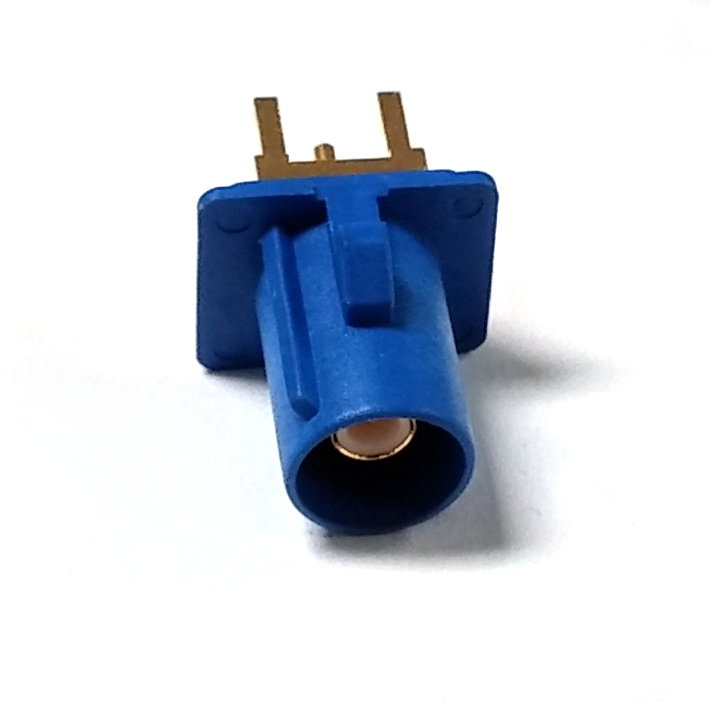

FAKRA Connector Types

FAKRA connectors are specialized RF (Radio Frequency) connectors developed primarily for automotive applications, ensuring secure, high-frequency signal transmission.

FAKRA (Fachkreis Automobil) connectors are modified SMB (SubMiniature version B) connectors housed in a plastic shell that adds mechanical stability, color coding, and keying. These enhancements ensure proper mating, vibration resistance, and safety in automotive apps (GPS, LTE, AM/FM, satellite radio and Bluetooth among others).

Key Features of FAKRA Connectors

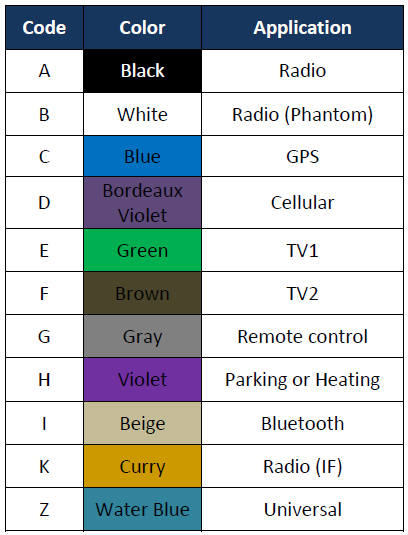

- Standardized Color Coding: Each FAKRA connector type is color-coded to prevent mismatches during installation.

- Durability: Built to withstand harsh conditions, FAKRA cables operate effectively in temperatures ranging from -40°C to 105°C.

- High-Frequency Performance: Capable of handling RF frequencies up to 6.0 GHz, making them suitable for various wireless technologies.

- Secure Locking Mechanism: Features a primary and secondary locking system to ensure stable and reliable connections.

- Versatility: Supports both single and double configurations, enhancing utility across different devices.

- FAKRA connector standard

Is a global standard for automotive connectors. The standard specifies a plastic housing and 14 mechanical, color-coded elements to prevent incorrect mating. Is standardized under USCAR and ISO 20860. The FAKRA standard specifications are:

| Impedance | 50 Ohm |

| Frequency Range | DC – 6 GHz |

| Voltage Rating | 335 Volts RMS Continuous |

| Dielectric Withstanding Voltage | 800 VRMS Max |

| VSWR (Return Loss) (3 – 6 GHz) | 1.6 (-13dB) Max |

| Insulation Resistance | 100 MΩ Min |

| Insertion Loss (3 – 6 GHz) | 0.45 dB |

| Power Handling | 95 W Max @ 1 GHz @ 25ºC |

| Mating Cycles | 100 Min |

| Coupling Mechanism | Push-On |

| Temperature Range | −40°C to +105°C |

FAKRA Connector Types (Coding)

There are primary FAKRA codes, each associated with a specific color and mechanical key to prevent misconnection. Here’s a summary:

Note: FAKRA Water Blue code is universal, meaning it can mate with any other type but doesn’t prevent mismating—used mostly in lab settings or generic applications.

FAKRA Type F connectors are color-coded brown, corresponding to RAL 8011. This standard is consistently documented across multiple reputable references:

- The Rosenberger FAKRA Number Code chart lists Type F as brown (RAL 8011). Rosenberger Group

- The Mouser Electronics FAKRA Number Code document also specifies Type F with a brown color code. Mouser Electronics+1Rosenberger Group+1

- The element14 Community’s comprehensive guide to FAKRA connectors confirms the brown color coding for Type F. element14 Community+1element14 Community+1

The brown color coding for Type F connectors is standardized under the USCAR and ISO 20860 specifications, ensuring consistency across manufacturers and applications. This coding helps prevent mismating and simplifies installation and maintenance in automotive RF and communication systems.

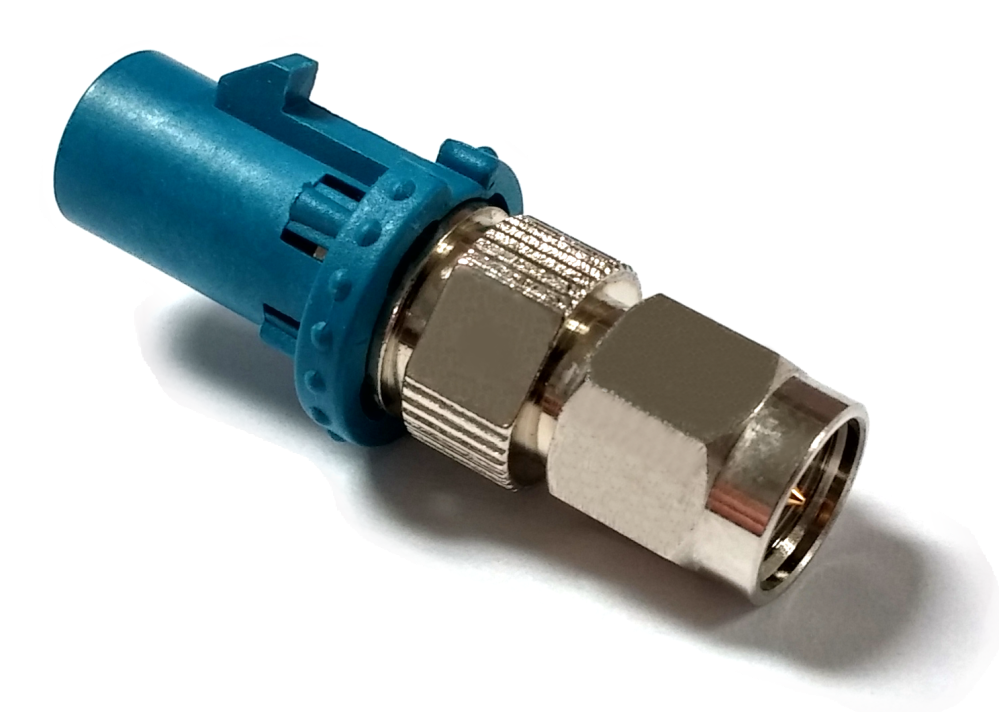

Gender and Mating

- FAKRA Plug (Male): Center pin, usually goes on the cable side.

- FAKRA Jack (Female): Center sleeve, usually on the device/housing.

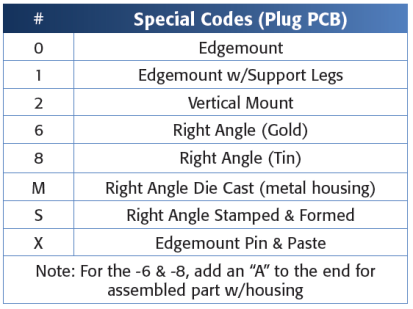

Variants and Mounting Styles

FAKRA connectors come in various configurations, including:

- Straight or right-angle

- PCB mount or panel mount

- Cable mount (crimp or solder)

- Sealed or unsealed

FAKRA connector standard

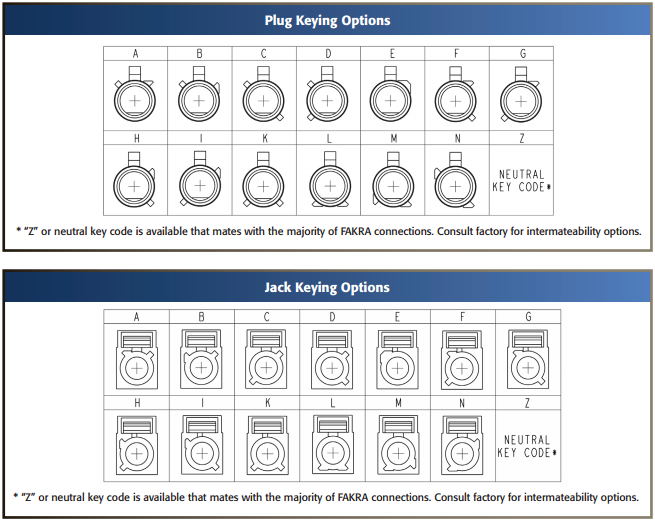

The mechanical keying system in FAKRA connectors is a crucial feature designed to prevent mismating, ensure correct signal routing, and maintain safety—especially in complex automotive and RF environments where multiple similar-looking connectors are used.

Here’s a breakdown of how the mechanical keying in FAKRA connectors works:

1. Unique Plastic Housing with Keying Features

Each FAKRA connector is built around a standard SMB RF interface, but it’s enclosed in a rectangular plastic housing that provides:

- Color coding (visual identification)

- Mechanical keying (physical differentiation)

The keying consists of protrusions (ridges) and notches (slots) on the outer housing that are unique for each FAKRA code (A through Z). These physical features prevent connectors with different key codes from mating.

2. Mating Compatibility is Code-Specific

- A FAKRA Plug (male) with code A (violet) can only mate with a FAKRA Jack (female) that has the same mechanical key and color (code A).

- Even if two connectors look similar in size and shape, if their keys don’t match, they won’t physically connect.

- This design eliminates human error during installation, particularly important in automotive manufacturing lines where speed and accuracy are critical.

3. FAKRA Z – The Universal Option

The exception is FAKRA Z (water blue), which has no keying. It can physically mate with any other FAKRA type. It’s typically used:

- In test environments

- For lab prototypes

- When a universal connection is acceptable

But Z-type connections sacrifice the safety of keying, so they’re not used in critical automotive systems.

4. Application Examples

- GPS (Code A, violet): Only connects to GPS modules

- Camera (Code H, orange): Only connects to camera inputs

- FM Radio (Code B, blue): Only plugs into FM antenna ports

This ensures that a GPS antenna isn’t accidentally plugged into an FM radio port, avoiding signal mismatches or system failure.

5. Assembly and Locking

Once aligned correctly (keyed ridges match), the connectors snap together with an audible “click”, indicating a secure connection. Most housings also include a locking tab or retention clip for vibration resistance.

Data Alliance offers a variety of FAKRA connectors and cables designed for RF applications, particularly in automotive, IoT, and wireless communication systems. Here’s an overview of the types available:

Types of FAKRA Connectors Available at Data Alliance

- FAKRA-Female to SMA-Female Cables

These cables connect FAKRA female connectors to SMA female connectors, facilitating integration between automotive-grade RF systems and standard SMA-equipped devices. - FAKRA-Female to RP-SMA-Female Cables

Designed to connect FAKRA female connectors to RP-SMA female connectors, these cables are suitable for applications requiring reverse polarity SMA interfaces. - FAKRA Type F Male to Female Extension Cable – 20 inches (52cm), LMR-100 Equivalent.

Data Alliance provides these cables in multiple lengths (e.g., 2-inch, 4-inch, 6-inch, 24-inch) to accommodate different installation requirements.

Applications

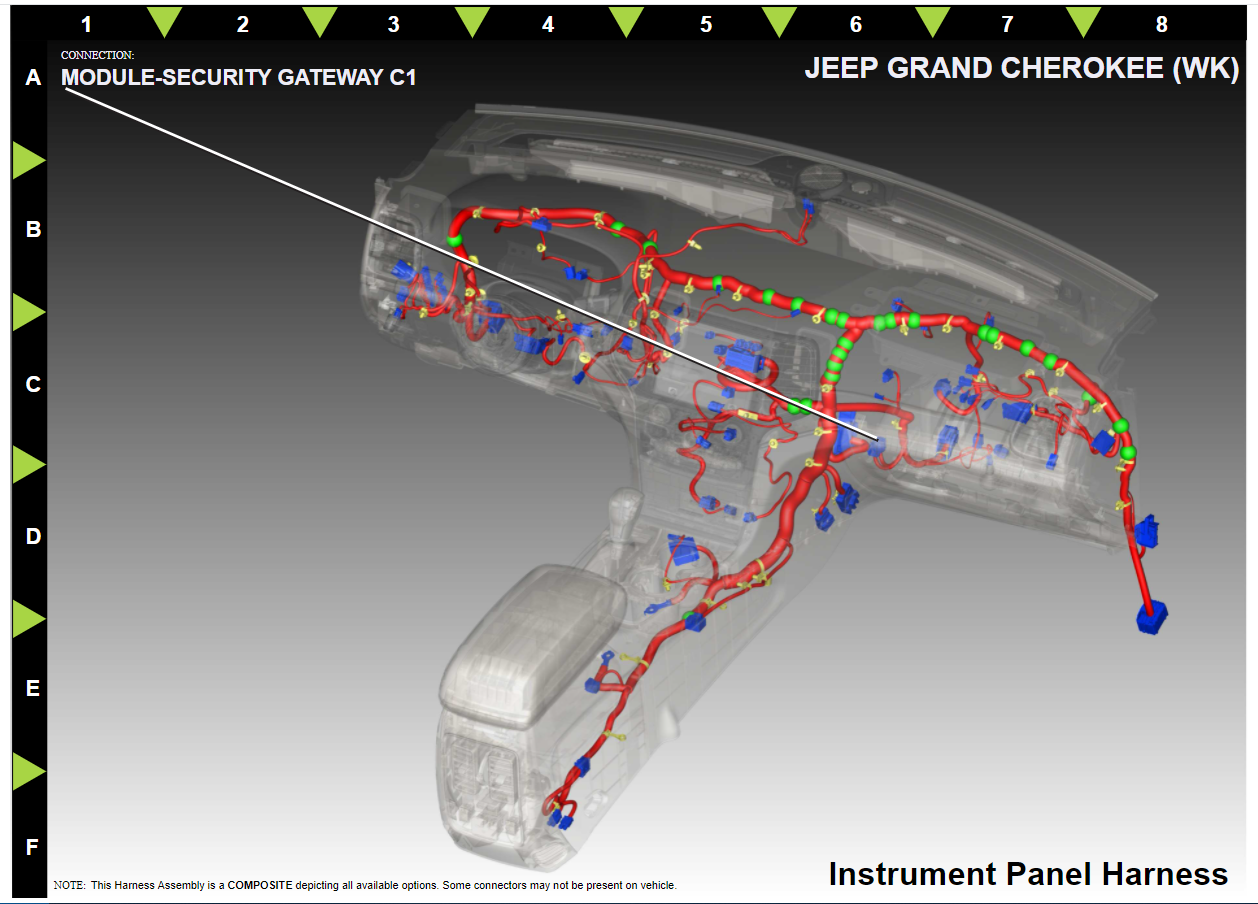

- Automotive: Used in GPS systems, in-vehicle entertainment, keyless entry, parking sensors, and more.

- IoT Devices: Ideal for devices requiring stable wireless connections in varying environmental conditions.

- Telecommunications: Enhances signal reliability in various telecommunication equipment.

For more detailed information and to explore their product offerings, you can visit Data Alliance’s FAKRA Cables & Adapters page.

Conclusions

For industries leaning heavily on IoT and automotive advancements, FAKRA connectors and cables seem to be the bridge leading to a more connected and efficient future.

The dynamic technological landscape has pushed the boundaries of wireless communication, resulting in more stringent requirements for connectors and cables. A remarkable entrant in this domain is FAKRA (Fachkreis Automobil), a German acronym that translates to “expert group for automotive.” These cables have made a significant impact in the domain of wireless technologies, particularly in automobile and IoT applications.

Source: FAKRA Connector Types and Codes