Category Archives: 3dprinting

3D Model 14: 3D-Printable Hyperboloidal Gear Model, .STL Format

Ethernet Cable Clip Repair by kohlmaker

These are replacement clips to fix broken ethernet cable clips. The clips attach to the Ethernet cable and replace the broken clip so that the cable stays locked into an Ethernet port. EDIT – For some reason Simplify3d doesn’t like this model. Cura works EDIT 2 – I recently posted some newer models that reflect the exact dimension per the Ethernet spec… that said I am not sure they work better or worse than the original design. I printed a few and tested them and they seem to work the same as the original design. Thanks to everyone who has downloaded these and posted comments! Enjoy!

The Ultimate box maker by Heartman

The file include now the Panel Maker. Check below in the Experimental area to download it. this project… My first try with OpenScad, the box is fully customizable. I hope you will enjoy with it, and will show us many boxes made with. If you play with the Fillet value you will go from the sharp to the round sides box If you want a chanfered box, set Resolution to 1. To export each single piece, just set the other elements to No value. The Top and Bottom Shells are the same, so it’s not necessary to export them two times, except if you use the PCB feet option. Check the animation below to see how to design your own box. You can change the text shape with any font listed here . Have fun 😉 Feb 12 2016 Minor bug fixed on unaligned hole when using more than 2mm thickness. March 01 2016 Added the decoration/holes options. (Thanks Ettie for your contribution) March 09 2016 Added PCB feet support, fixed the shell artefact on export mode. March 01 2018It Seems, since few month the online customizer doesn’t works, some lib missing. it’s not under my hands, ask to makerbot/thingiverse staff. THE solution is, downloading the newest – Development Snapshot – release of Openscad software and activate in the Edit>preference>features menu and check the “Enable customizer” option. link:OpenScad-Customizer Please, read as well. The PCB feet dimensions are all starting from the foot axis center. it’s not the circuit board size, holes center only(!) Check below, some animated pictures showing how to use the Ultimate Box maker online.

Fusion 360 Keyboard Shortcuts, Hotkeys & Commands Guide | Autodesk

Prusa Leveling Guide

Source: Prusa Leveling Guide

Customizing PrusaSlicer g-code — Bob’s Project Notebook beta documentation

Tutorial for setting up P2PP in PrusSlicer 2.0. Slice models directly from PS2 to the Palettte 2! – YouTube

tomvandeneede/p2pp: Palette2 Post Processing tool for Slic3r

SKS Bottle & Packaging – Cap and Neck Finishes

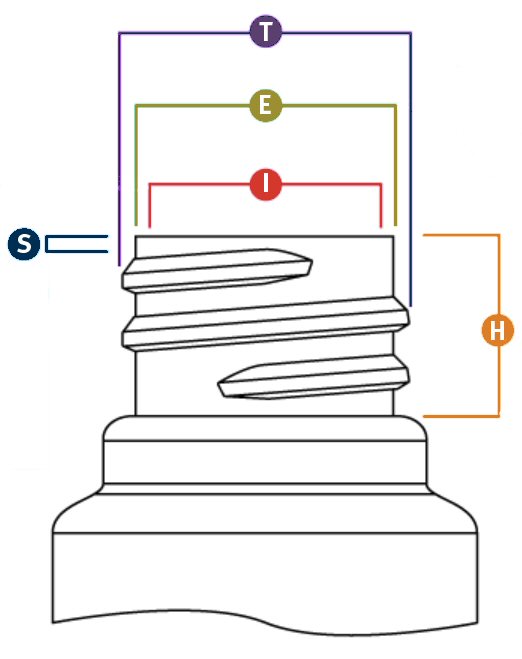

Cap and Neck Finishes

A container’s neck finish holds the cap, stopper, or closure with protruding threads. A container and its corresponding cap must have matching finishes. For example, a 24/400 bottle will only accept a 24/400 closure.

Screw thread or continuous thread closure sizes are expressed with two numbers separated by a hyphen or slash. The first number refers to the millimeter diameter measured across the inside of the cap’s opening or the outside of the bottle’s threads. The second number refers to the thread style, “GPI” or “SPI” finish. The Glass Packaging Institute (GPI) and Society of the Plastics Industry (SPI) are responsible for establishing uniform standards for glass and plastic container neck finishes. The closure industry does not necessarily adhere to the same standards, so it is often best practice to purchase containers and caps from the same manufacturer when possible.

For information about proper torque when applying closures to containers, visit our Torque Guide page.

“T” Dimension

Outside diameter of the thread. The tolerance range of the “T” dimension will determine the mate between bottle and closure.

“E” Dimension

Outside diameter of the neck. The difference between the “E” and “T” dimensions divided by two determines the thread depth.

“I” Dimension

Inner diameter of bottle neck. Specifications require a minimum “I” to allow sufficient clearance for filling tubes. Linerless closures w/ plug or land seal & dispensing plugs/fitments require controlled “I” dimension for proper fit.

“S” Dimension

Measured from the top of the finish to the top edge of the first thread. The “S” dimension is the key factor that determines orientation of the closure to bottle and the amount of thread engagement between the bottle and cap.

“H” Dimension

The height of the neck finish. Measured from the top of the neck to the point where the diameter “T”, extended down, intersects the shoulder.

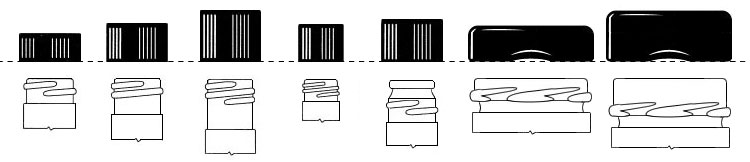

Common GPI / SPI Neck Finishes

- 400

- 410

- 415

- 425

- 430

- 2030

- 2035

- 400: 1 thread turn

- 410: 1.5 thread turns

- 415: 2 thread turns, narrow threads

- 425: Buttress Finish – thick threads & top bead (better seal, more application torque)

- 2030: Lug Finish – Non-continuous threads

- 2035: Lug Finish – Non-continuous threads, tall “H” dimension

How to Measure a Neck Finish

To find a cap’s diameter, measure from one side of the inner wall to the opposite side. Calculate a bottle’s neck finish by measuring the diameter of the outermost threads. The resulting millimeter measurement will be the “T” dimension.

Then, see how many times the threads pass one another to determine the finish.

(ex. 24 mm “T” dimension with 1.5 thread turns = 24/410 neck finish)

Source: SKS Bottle & Packaging – Cap and Neck Finishes

See also: http://www.qorpak.com/pages/HowtoSelecttheRightSizeCapforyourBottle